Factory

Our Manufacturing Process & Technology

Ayoto’s factory is located in Keraniganj, just an hour away from the heart of Dhaka city. The 25,000 sft factory is equipped with the most modern technology for manufacturing solid wood and panel board furniture & modular kitchen. We follow a minute based production strategy which allows to maximize efficiency and optimize the price for customers.

Factory

Our Manufacturing Process & Technology

Ayoto’s factory is located in Keraniganj, just an hour away from the heart of Dhaka city. The 25,000 sft factory is equipped with the most modern technology for manufacturing solid wood and panel board furniture & modular kitchen. We follow a minute based production strategy which allows to maximize efficiency and optimize the price for customers.

CNC Nesting Machine

Our nesting machines are controlled by a computer and provide a level of efficiency, accuracy and consistency that would be impossible to achieve through a manual process. The pre-programmed computer software dictates the cutting, routing and boring of panels. As a result, we can produce boards in less time, reduce waste and eliminate the risk of human error.

CNC Nesting Machine

Our nesting machines are controlled by a computer and provide a level of efficiency, accuracy and consistency that would be impossible to achieve through a manual process. The pre-programmed computer software dictates the cutting, routing and boring of panels. As a result, we can produce boards in less time, reduce waste and eliminate the risk of human error.

CNC 4-Axis Wood Lathe

Creates perfect replications of any design within minutes with a level of accuracy and consistency that would be impossible to achieve through a manual process. This results in high quality parts in the least amount of time, radically improving our efficiency and enabling us to pass on the superior performance and cost advantages to our clients.

CNC 4-Axis Wood Lathe

Creates perfect replications of any design within minutes with a level of accuracy and consistency that would be impossible to achieve through a manual process. This results in high quality parts in the least amount of time, radically improving our efficiency and enabling us to pass on the superior performance and cost advantages to our clients.

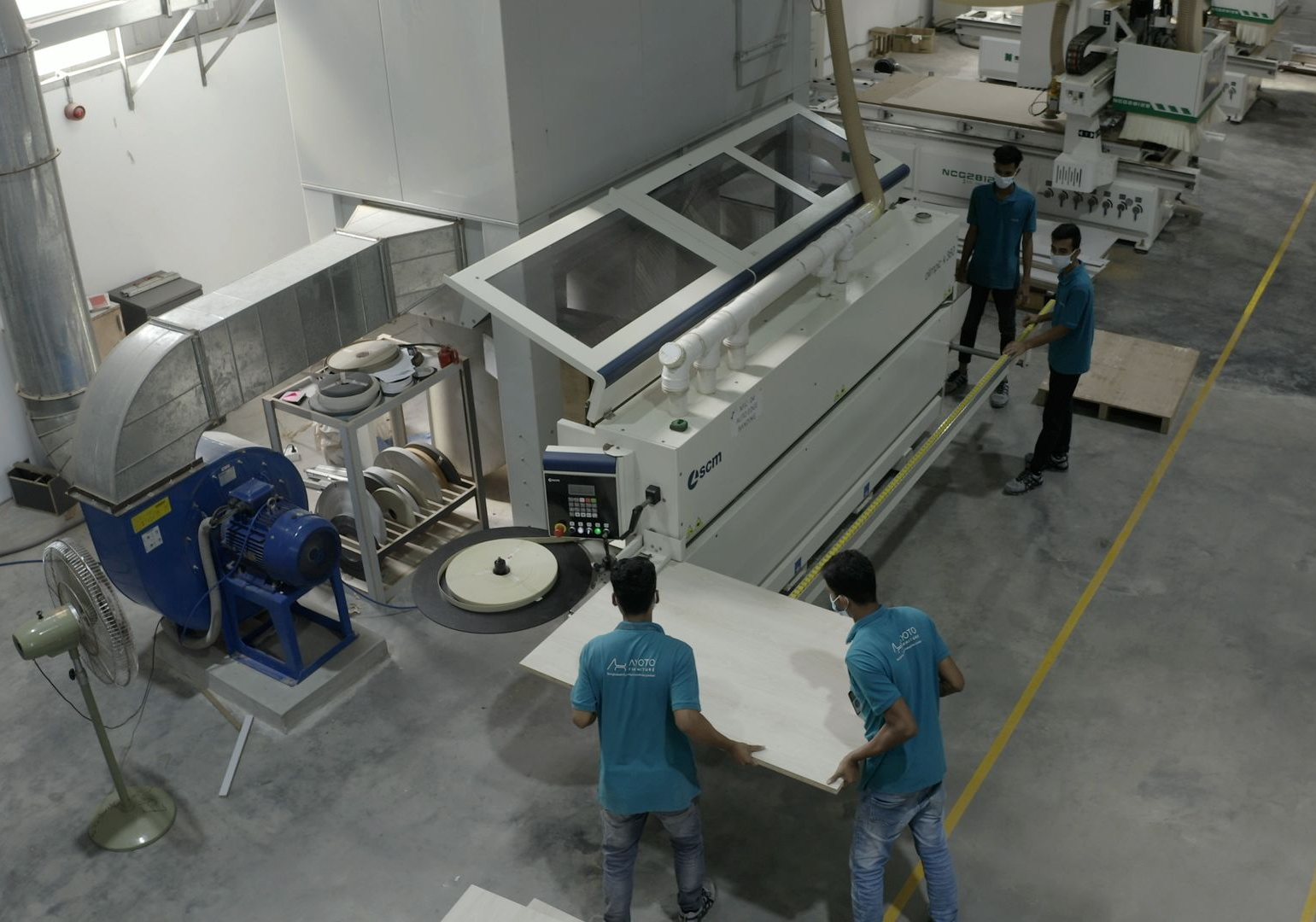

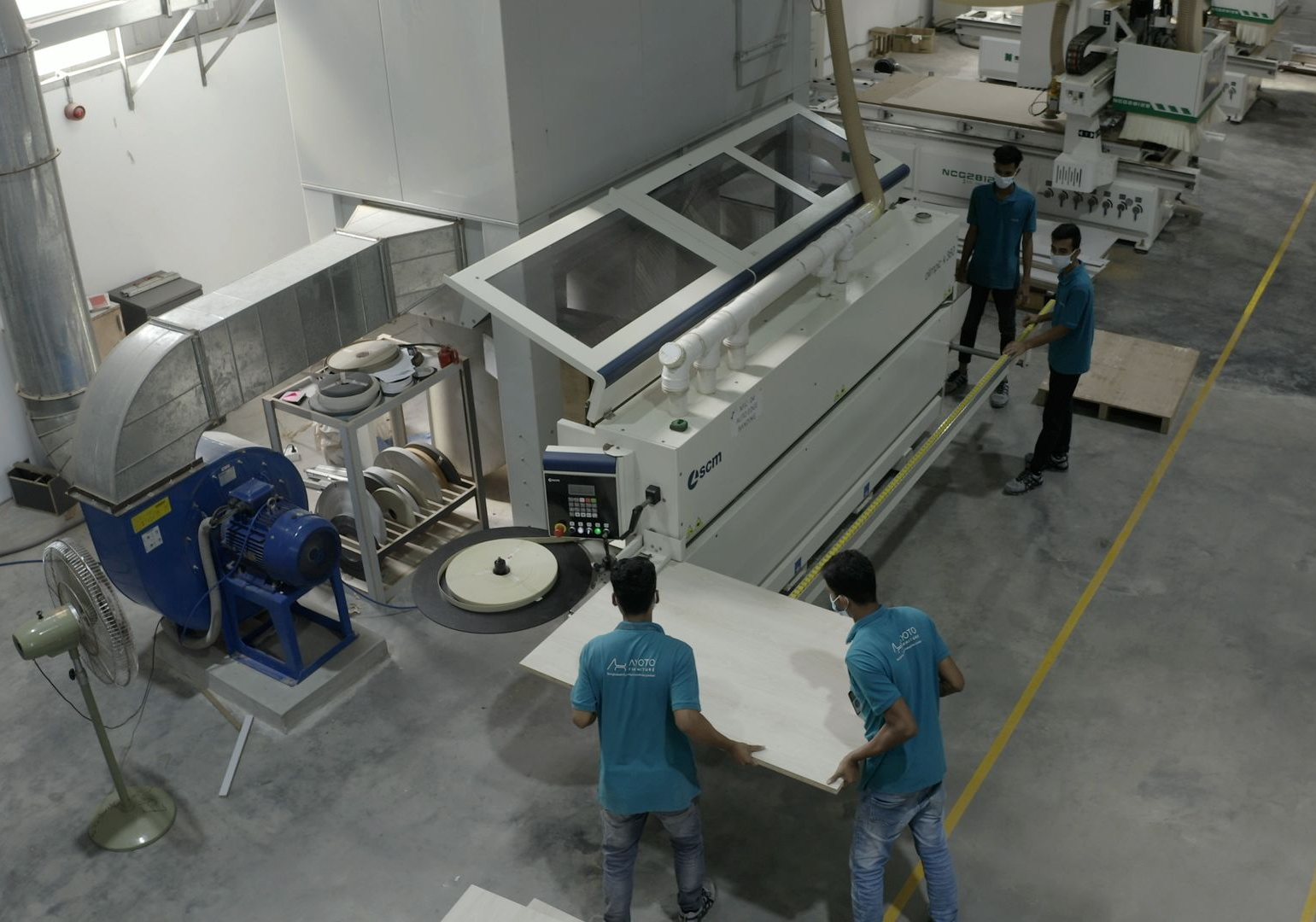

Edge Banding Machine

Edge banding is one of the most crucial steps to ensure flawless finishing and durability of the furniture. It is the process of applying a thin strip of material, known as edge banding or edge tape, to the exposed edges of panels, boards, or other surfaces to give them a finished and refined appearance. Our European edge banding machine automates this entire process, making it more efficient and precise.

Edge Banding Machine

Edge banding (sealing the exposed edges of wood) is one of the most crucial steps to ensure flawless finishing and durability of the furniture. Our edge banding machine tracks the model and the high-frequency and high-speed motor fast cutting structure to ensure smoothness and flatness while cutting the board. It glues the double-sided edge sealing plate and edge sealing material ensuring firm adhesive. The machine also finishes, scrapes and polishes the boards to give a perfect finish that simply is not possible to achieve manually.

Thermofoil Vacuum Membrane Press

This machine allows us to use thermofoils which are available in hundreds of shades and designs. Because thermofoil surfaces have a smooth vinyl surface, they resist the buildup of dust and grime. Whatever does stick to your furniture surface is easily removed with the occasional wipe down with a damp cloth or soapy water for tougher dirt. They are also stain-resistant, making tea, coffee, and gravy easy to wipe away.

Thermofoil Vacuum Membrane Press

This machine allows us to use thermofoils which are available in hundreds of shades and designs. Because thermofoil cabinets have a smooth vinyl surface, they resist the buildup of dust and grime. Whatever does stick to your cabinet is easily removed with the occasional wipe down with a damp cloth or soapy water for tougher dirt. They are also stain-resistant, making tea, coffee, and gravy easy to wipe away.

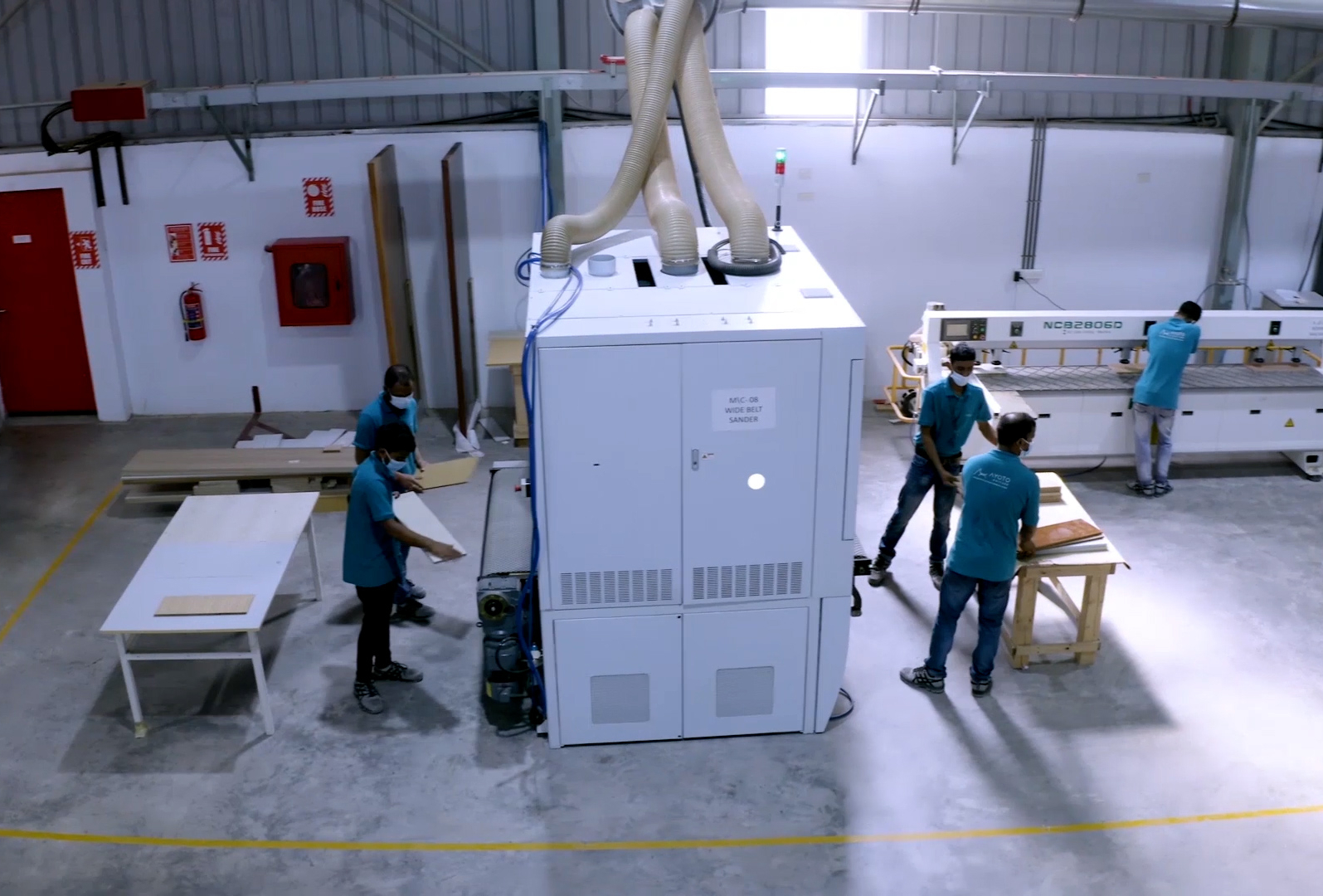

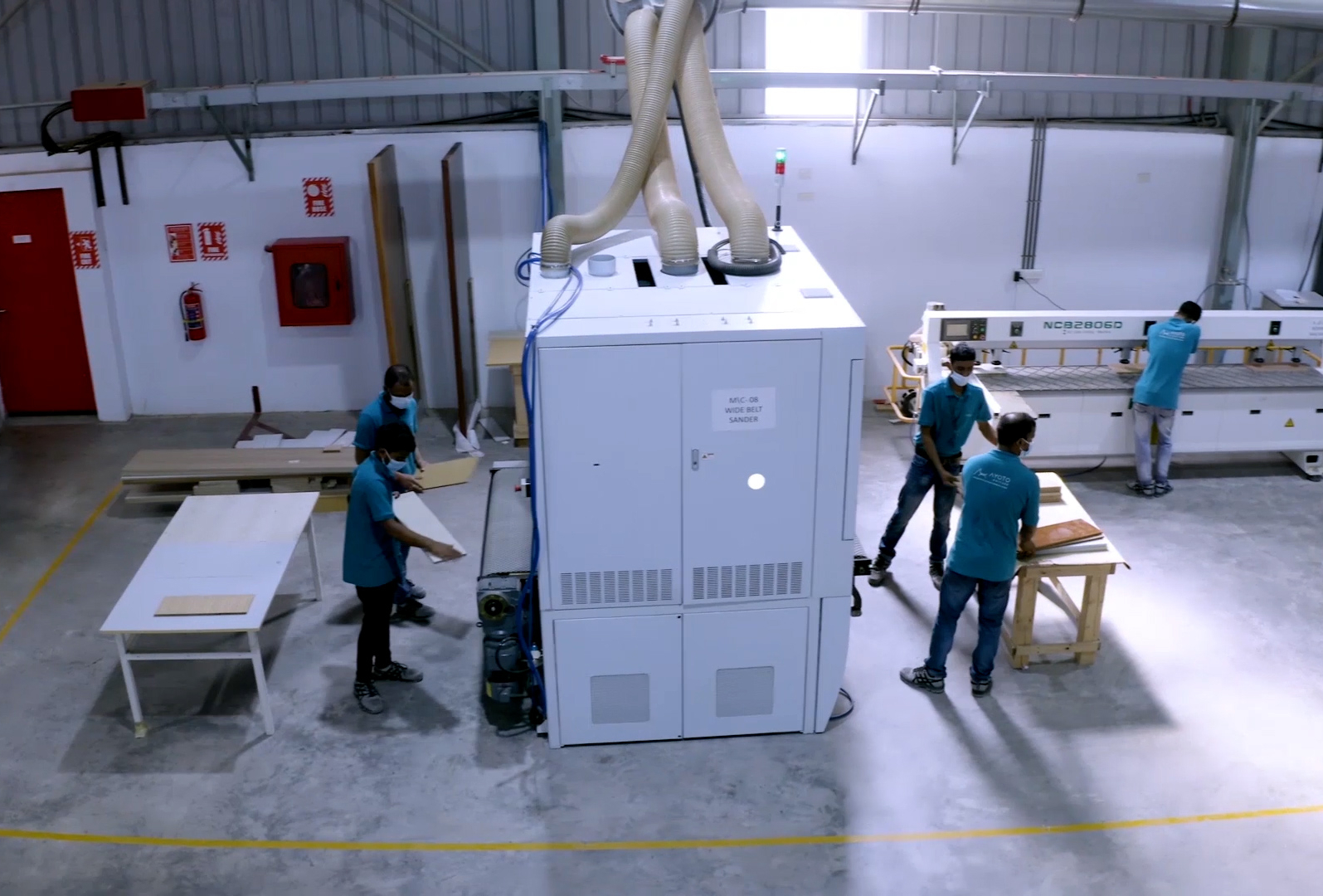

Wide Belt Sander Machine

Our wide belt sander machine rapidly removes and levels the wood and helps bring smooth finish to rough boards extremely fast. Unlike manual sanding, if there are accidental scratches made during processing, the sanding machine can easily cover it up in the next pass.

Wide Belt Sander Machine

Our wide belt sander machine rapidly removes and levels the wood and helps bring smooth finish to rough boards extremely fast. Unlike manual sanding, if there are accidental scratches made during processing, the sanding machine can easily cover it up in the next pass.

UV Roller Coater & Dryer

Enables us to use UV coating which keeps the furniture looking newer for longer. UV coated surfaces are also scratch resistant and give greater gloss and better protection than an aqueous coating or lamination.

UV Roller Coater & Dryer

Enables us to use UV coating which keeps the furniture looking newer for longer. UV coated surfaces are also scratch resistant and give greater gloss and better protection than an aqueous coating or lamination.

Central Dust Collection

Dust particles in the air can settle on furniture surfaces during production, leading to defects and imperfections in the finished products. Our central dust collection system removes airborne dust and ensures a higher quality final product. It also helps maintain a cleaner and healthier workspace for employees.

Central Dust Collection

Dust particles in the air can settle on furniture surfaces during production, leading to defects and imperfections in the finished products. Our central dust collection system removes airborne dust and ensures a higher quality final product. It also helps maintain a cleaner and healthier workspace for employees.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.